5 Keys To A Better Brewery Production Schedule

Creating a brewery production schedule requires careful planning and consideration of various factors, such as the types of beer to be produced, the brewing equipment available, and the production capacity of the brewery.

Here are 5 tips for creating a successful brew day or brewery production schedule:

-

Plan ahead: It's essential to plan the production schedule well in advance, taking into account the demand for each beer type, the availability of ingredients, and the time required for brewing, fermentation, conditioning, and packaging.

-

Consider the lead time for ingredients: Different beer styles require different types of ingredients, and some ingredients may have longer lead times or limited availability. Therefore, it's important to plan ahead for ingredient ordering and delivery.

-

Optimize production capacity: To maximize efficiency and minimize downtime, it's important to optimize the use of brewing equipment and production space. This can include brewing double batches since you'll have all the ingredients already in place, or brewing beers at the same time that use similar ingredients and brew methods, saving brewing those complex process brews (such as sour beers) while your lagers are fermenting.

-

Prioritize consistency: Consistency is key when it comes to beer production, so it's important to maintain consistent brewing practices and follow established recipes and procedures. The brewer should be accurately documenting all the steps and ingredients used throughout the brewing process, and even the packaging process, to provide your customers with consistent quality.

-

Be flexible: Despite careful planning, unexpected issues can arise, such as equipment breakdowns or ingredient shortages. Therefore, it's important to be flexible and able to adjust the production schedule as needed to meet demand and maintain quality.

Overall, a successful brewery production schedule requires careful planning, attention to detail, and the ability to adapt to unexpected challenges.

How Can Brewery Software Help?

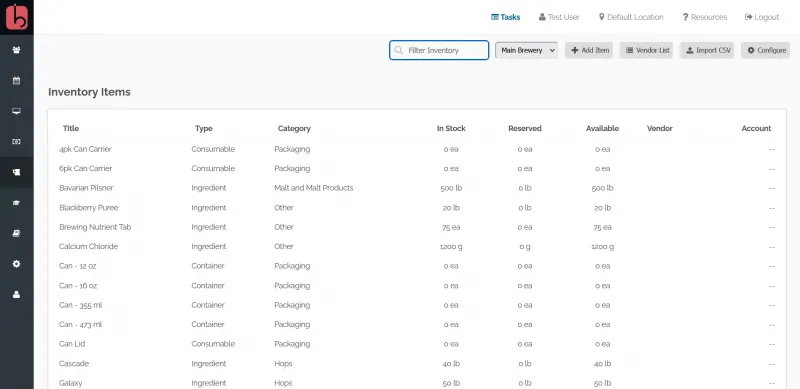

Brewery production software like BarSight can be a powerful tool for the brewing industry. Creating and managing production schedules, organizing a list of your inventory, customers, and suppliers as well as your purchase history and customer sales orders. Here's how it can help with each of the tasks mentioned above:

-

Planning ahead: BarSight can help with forecasting the stock levels of your raw materials and packaging materials.

With all your brews scheduled on the production planning page, BarSight is able to generate a report that you can view the forecast day-by-day to monitor your stock levels. This allows you to plan when to order raw materials ahead of time, possibly even saving you money with last-minute shipment costs.

-

Lead time for ingredients: BarSight can track the availability of ingredients in all of your locations and provide alerts when inventory levels are low. This can help the brewery plan ingredient orders in advance to avoid delays in production or additional shipping costs.

-

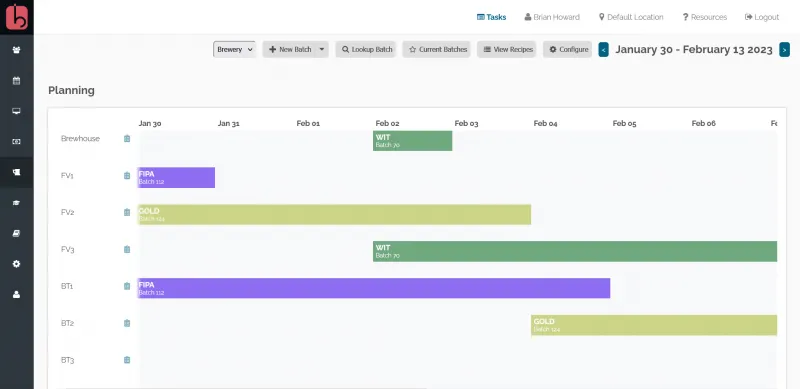

Optimizing production capacity: BarSight can help optimize production by providing real-time visibility into equipment usage and scheduling.

The software can help brewers and production staff visualize the brewery and optimize the use of production space, minimizing downtime and maximizing efficiency.

-

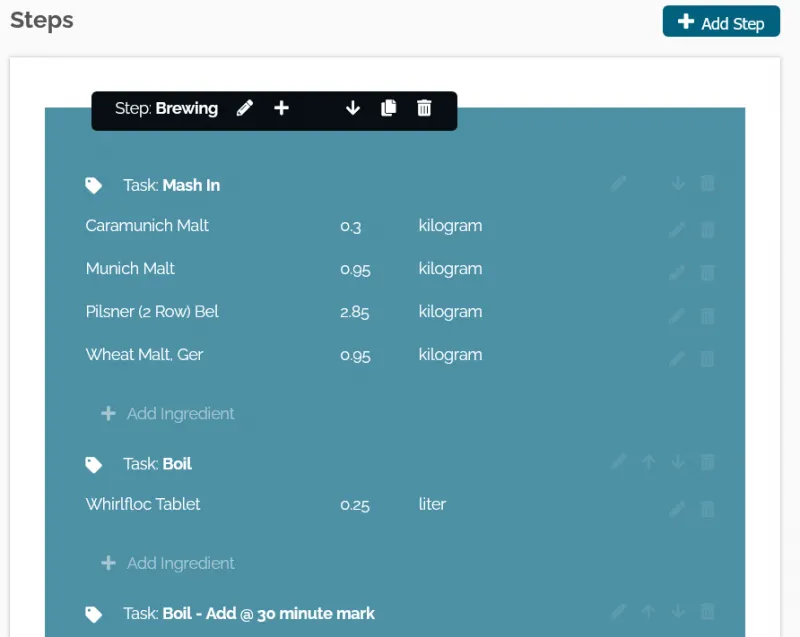

Prioritize consistency: BarSight can help ensure consistency by providing centralized recipe management and standard operating procedures.

Each recipe can contain notes at each step and task of the brew process, such as sparge tempurates and target pH levels. This can help ensure that brewing practices are consistent across all batches and all brewers.

-

Be flexible: BarSight can help with flexibility by providing real-time visibility into production status and inventory levels. This can help the brewery adjust the production schedule as needed to meet demand or respond to unexpected issues.

Overall, brewery production software like BarSight can help with all critical aspects of production scheduling by providing real-time visibility, predictive analytics, along with optimized scheduling throughout the brewing process. This can help breweries optimize their production process, minimize downtime, produce and maintain consistent quality across all batches.

Try our software, hassle free and instantly

Register today, and get instant access to our brewery inventory software. Try it out for yourself, import recipes and inventory, create tanks, and take it for a spin!